Table of Contents

Abrasive materials are a core part of many industrial processes. From smoothing raw surfaces to preparing materials for coating or finishing, abrasives affect both efficiency and final quality. Choosing the right products is important, but choosing the right abrasive supplier in Malaysia matters just as much.

A reliable supplier does more than sell abrasives. They help you select the right material, grit, backing, and format for your application. They also ensure consistency, availability, and performance over time. This article explains the main types of abrasive materials and what you should expect from a supplier that truly understands industrial needs.

What Are Abrasive Materials Used For?

Abrasives are used to remove material, smooth surfaces, clean substrates, and create controlled finishes. They are essential in industries such as metalworking, woodworking, automotive refinishing, and collision repair.

Common tasks include deburring sharp edges, levelling uneven surfaces, removing old coatings, and preparing materials for painting or bonding. Because these tasks vary widely, abrasives must be matched carefully to the job.

A capable abrasive supplier in Malaysia should understand these use cases and guide customers towards suitable products rather than offering one-size-fits-all solutions.

Coated Abrasives: The Industry Standard

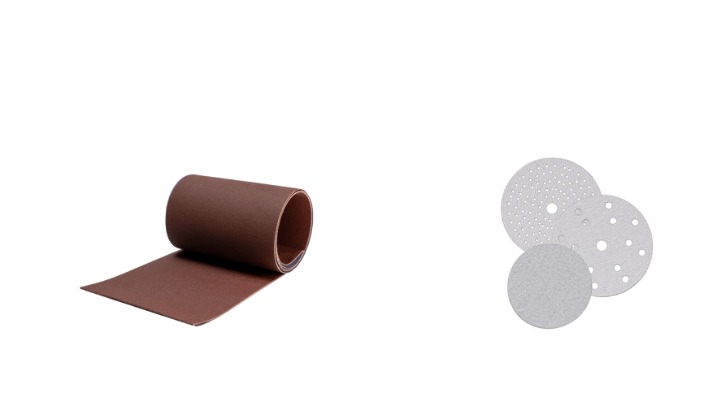

Coated abrasives are among the most widely used abrasive products. They consist of abrasive grains bonded to a backing material such as paper, cloth, or polyester.

A good supplier should offer coated abrasives in multiple forms, including sheets, rolls, discs, and belts. These products are commonly used for sanding wood, metal, and composite materials.

Beyond format, backing type matters. Paper backings suit lighter work, while cloth and polyester backings handle heavier loads and repeated use. Grit range and grain type also influence cutting speed and surface finish.

Abrasive Paper and Cloth Explained

Abrasive paper is typically used for hand sanding or light machine sanding. It offers flexibility and ease of use, making it suitable for finishing tasks and surface preparation.

Abrasive cloth, often made from cotton or polyester, provides greater strength and durability. It is commonly used in metalworking and heavy sanding applications where tear resistance is important.

Your supplier should be able to explain when paper is sufficient and when cloth is the better choice, based on material hardness and workload.

Non-Woven Abrasives for Surface Conditioning

Non-woven abrasives are designed for cleaning, blending, and finishing rather than aggressive material removal. They are commonly used to remove light rust, blend welds, or create uniform surface textures.

These abrasives are especially useful in automotive refinishing and metal fabrication, where surface consistency is critical. A strong supplier will carry multiple grades and formats to suit different conditioning tasks.

Non-woven products also reduce the risk of gouging, making them ideal for controlled finishing work.

Polyester Cloth Abrasives for Demanding Applications

For high-stress environments, polyester cloth abrasives offer strength and stability. They are heat-treated and tear-resistant, making them suitable for high-speed machinery and continuous operation.

Industries that require aggressive sanding or grinding often rely on these products. A supplier should stock these abrasives and understand where they provide value over lighter alternatives.

Product durability directly affects productivity, so guidance in this area is important.

Consistency and Quality Control

Abrasive performance must be consistent. Variations in grain size, bonding, or backing quality can lead to uneven finishes, increased rework, and wasted time.

A reliable supplier ensures tight quality control and consistent product standards. This consistency allows operators to trust that results will remain stable across batches and over time.

Consistency is especially important for manufacturers who rely on predictable processes.

Custom Solutions and Application Support

Not all applications fit standard products. Some industries require abrasives tailored to specific machines, materials, or finishing requirements.

A strong supplier offers custom manufacturing or product adaptation when needed. This may involve adjusting grit combinations, backing materials, or dimensions to suit specialised workflows.

Equally important is technical support. Suppliers should help customers troubleshoot issues such as premature wear, surface defects, or inefficient sanding.

Reliable Supply and Industry Coverage

Downtime caused by missing consumables can disrupt production schedules. A dependable supplier ensures steady availability and timely delivery.

They should also serve a broad range of industries, from woodworking and metal fabrication to automotive and collision repair. This breadth usually reflects deeper technical knowledge and a more comprehensive product range.

What to Look for When Choosing a Supplier

When evaluating an abrasive supplier, consider more than price. Look at product range, technical expertise, consistency, and long-term support. A supplier who understands your processes can help improve efficiency and reduce waste.

The right partner adds value through advice, reliability, and performance—not just through sales.

Why Sohadu Is a Trusted Abrasive Supplier in Malaysia

When it comes to choosing an abrasive supplier in Malaysia, Sohadu brings decades of experience, technical knowledge, and manufacturing capability. With a wide range of coated abrasives, non-woven products, and industrial-grade solutions, Sohadu supports industries such as metalworking, woodworking, automotive refinishing, and collision repair.

As both a manufacturer and supplier, Sohadu offers consistent quality, custom manufacturing options, and reliable supply for businesses of all sizes. Their focus on performance, durability, and application-specific solutions helps customers achieve better surface finishes with less downtime.

If you are looking for an abrasive partner who understands your industry and delivers dependable results, contact Sohadu today to explore their full range of abrasive products and tailored solutions.

Achieve superior surface finishes with precision-engineered solutions from Sohadu Industries Sdn Bhd. Contact today to discuss your abrasive needs with Malaysia’s trusted industrial partner.